Box Girder Submerged Arc Welding System

Enhance your box girder production with this high-efficiency Submerged Arc Welding System. Featuring a twin-head automatic welding trolley and DC power source, it ensures stable performance, smooth seams, and consistent weld quality for structural steel fabrication.

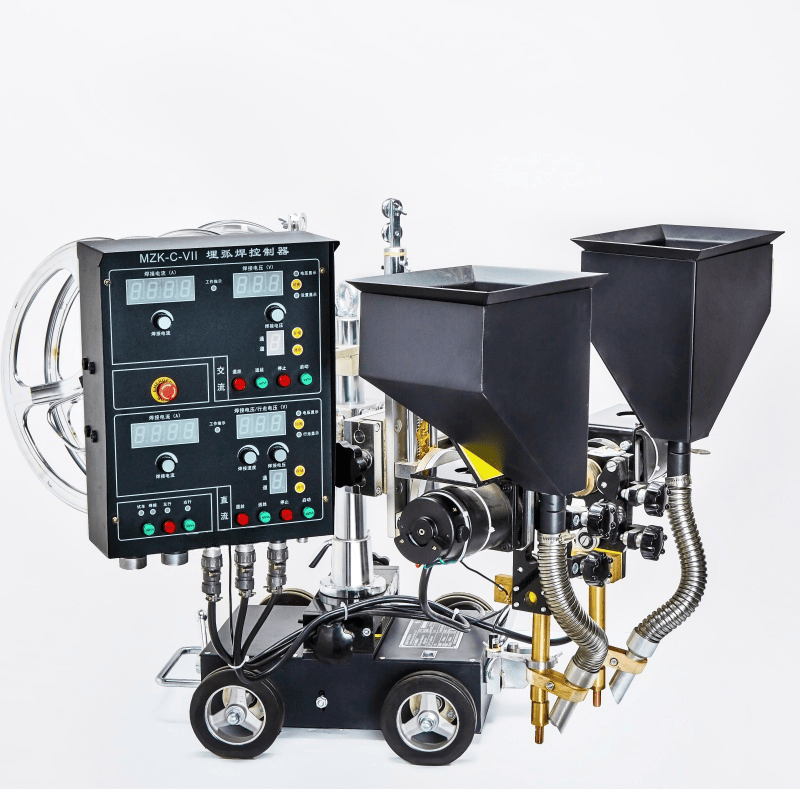

1. Product Name: WT-XL Box Beam Submerged Arc Welding System

2. Power Supply: MZ-F Series DC Submerged Arc Welding Power Source

3. Design: Twin-head automatic welding trolley for parallel seam welding

4. Welding Materials: Carbon steel, low-alloy steel, stainless steel, heat-resistant steel, composite steel

5. Welding Efficiency: High-speed, stable welding performance with automated control

6. Ideal for: Box beam,column welding in structural steel and heavy industry

- Overview

- Recommended Products

System Description

The welding effect of the system is excellent, and the weld quality is high, the stability is good, the production efficiency is high, and the reliability is strong. Box beam submerged arc welding system also has high adaptability, combined with many years of manufacturing welding equipment technology, experience specifically designed and developed for the main weld of box beam/column. High efficiency, stable performance, easy to operate.

Place of Origin: |

China |

Brand Name: |

IKING |

Model Number: |

IK-2MZ-F-WT-XL |

Certification: |

CE/ISO |

Minimum Order Quantity: |

1 unit |

Packaging Details: |

Plywood case for sea shipment |

Delivery Time: |

10~20 days |

Payment Terms: |

40%TT to confirm the order, balance be paid before shipment |

Supply Ability: |

300 units/month |

System Characteristics

1. Welding system adopts welding car design, which can realize automatic welding of box beam and column. Dual head design enables the equipment is more efficient.

2. The use of DC submerged arc welding power supply, to ensure the stability and consistency of welding quality. Carbon structural steel can be welded and low alloy structural steel, heat resistant steel and other composite steel and other steel types.

This welding system is an efficient submerged arc welding machine composed of two MZ-F series DC submerged arc welding power sources and a WT-XL box beam trolley. The trolley adopts double head design, which can weld parallel welds to box beams and columns at the same time. It is an ideal welding equipment for box beams and columns.

WT-XL box girder trolley features

The welding machine is a welding car type, equipped with DC arc welding power supply, which can automatically weld under the flux layer.The car adopts double head design, which can weld two parallel welds at the same time. It is the ideal welding equipment for box beam.Weldable steel types include carbon structural steel, low alloy structural steel, stainless steel, heat-resistant steel and composite steel.

1. Flux baffle in the welding process to block the flux leakage, effectively protect the weld pool.

2. Vertical feed screw nut and optical axis guide, simple structure, small size, light weight, flexible rotation.

3. The horizontal adjustment using screw nut, linear guide structure, can adjust the horizontal position of any head on either side.

Description of the MZ-F power supply

MZ-F series submerged arc welding machine can weld carbon structural steel, low alloy structural steel, no Rust steel, heat-resistant steel and composite steel, etc. The power supply adopts thyristor rectifier, can Rapid automatic compensation for network fluctuations to ensure arc stability, Easy adjustment of output current.

-MZ-1250F Power supply -

MZ-F submerged arc welding machine introduces the minimum trigger Angle protection control method of three-phase circuit, so the equipment can also provide DC output for steelmaking and rapid quenching equipment, which makes up for the shortcomings of the first generation of products. The rated welding current of the welder corresponds to the rated load persistence rate. When the load persistence rate increases, the maximum output current of the welder decreases accordingly.

Application:

Submerged arc welding (SAW) is widely used in many heavy industrial sectors due to its high welding efficiency, stable weld quality, and aesthetically pleasing weld finish. These applications primarily include:

1. Shipbuilding: Long welds and thick plate splicing in ship structures.

2. Bridge construction: Welding of main girders and box girders in large steel bridges.

3. Pressure vessels: Welding of circumferential and longitudinal seams in storage tanks, boilers, and reactors.

4. Construction machinery: Welding of large structures such as excavators, cranes, and bulldozers.

5. Marine engineering: Welding of offshore platforms and oil pipelines.

6. Steel structure manufacturing: Welding of steel components in factories, stadiums, and high-rise buildings.

7. Pipeline construction: On-site welding of long-distance oil and gas pipelines (often using automated welding trolleys).

8. Rolling stock: Welding of underframes for railway freight cars and large passenger vehicles.