- Overview

- Recommended Products

Place of Origin: |

CHINA |

Brand Name: |

IKING |

Certification: |

CQC |

Minimum Order Quantity: |

1 UNIT |

Packaging Details: |

Plywood Wooden Case |

Delivery Time: |

3-5 days |

Payment Terms: |

40%TT in advance, 60%Balance be baid before delivery |

Supply Ability: |

5 units/day |

Description:

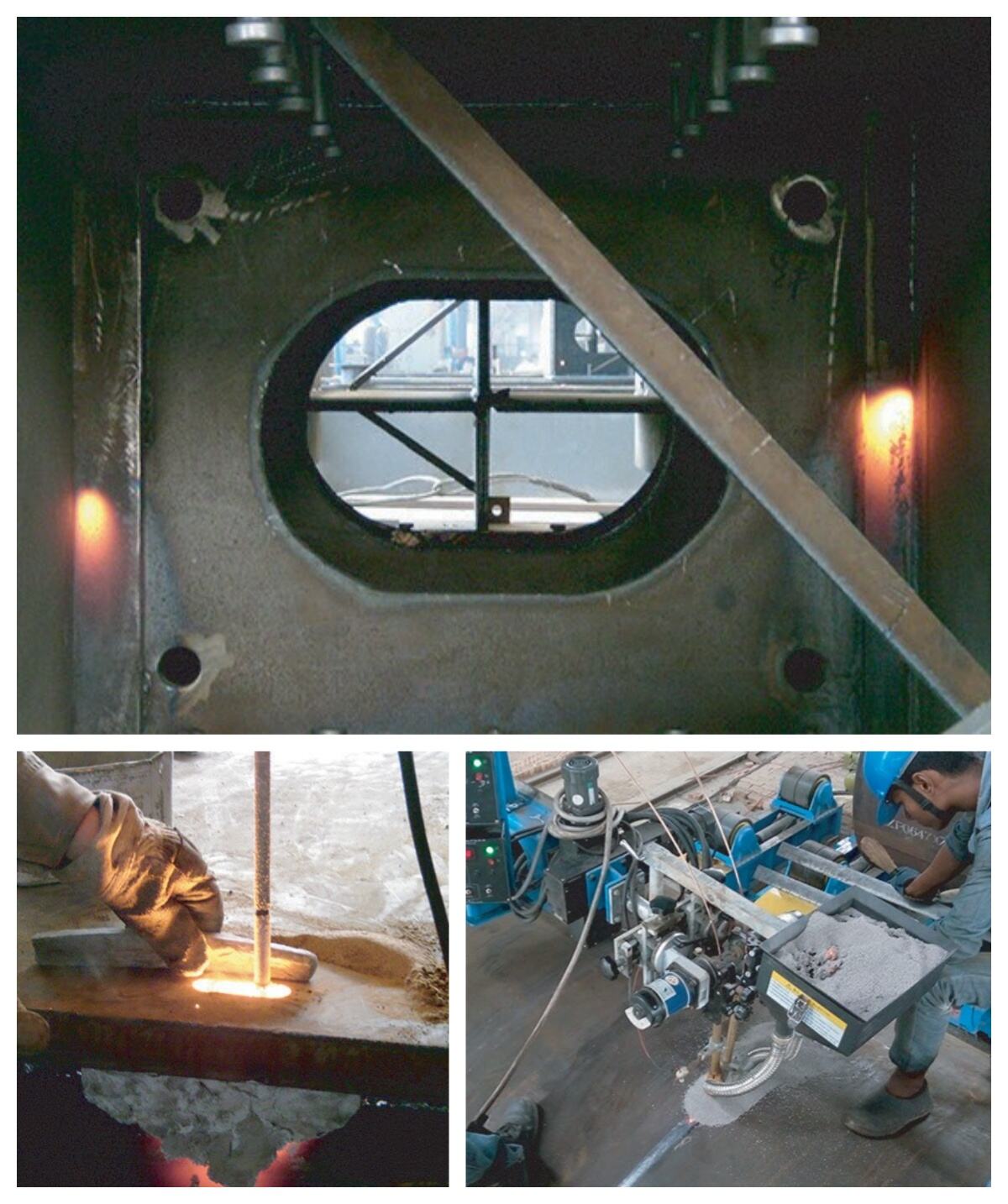

Wire pole electroslag welding machine is an electroslag welding equipment that uses welding wire as electrode, and the wire is fed into the slag pool through the non-consumable electroslag welding gun and conductive nozzle. It is mainly used for efficient welding of vertical weld seams in steel structures, and is especially suitable for the welding of box-type columns and box-type beam bulkheads. It can weld very thick workpiece at one time, high welding speed, smooth welding process and not easy to produce spatter, with high melting rate.

Efficiency, high performance, stable and easy to operate

Applications:

1、Thickness of steel plate: 16-100mm

2、Steel type: low carbon steel, low alloy steel, medium carbon steel, refractory steel, etc.

3、Welding seam length: Maximum 1680mm (depends on the length of electroslag welding torch)

4、Welding seam structure: T-welding and butt-welding.

Translated with www.DeepL.com/Translator (free version)

Specifications:

1.1.1 H7 Wire Electroslag Welding Power Source (IGBT)

1.1.2 Power Source Specifications

Name |

Unit |

ZH7-1000 |

Weight |

KG |

95 |

Full Load Efficiency |

% |

89% |

No-load Voltage |

V |

120 |

Rated Welding Voltage |

V |

60 |

Rated Input Current |

A |

128 |

Full Load Power Factor |

- |

0.88 |

Rated Welding Current |

A |

1000 |

Voltage Output Range |

V |

22-60 |

Current Output Range |

A |

90-1000 |

Power Supply Rated Input Capacity |

KVA |

? |

Rated Load Duty Cycle |

% |

100 |

Welding Cable Cross-sectional Area |

mm² |

140 or 70×2 |

Three-phase Input Wire Cross-sectional Area |

mm |

16 |

User Air Switch Capacity |

A/V |

250/380 |

Power Input Voltage/Frequency |

V/Hz |

AV3X380/50 |

Overall Dimensions (L×W×H) |

mm |

823×371×840 |

Wire Feeder

Name |

Parameter |

Wire Feeding Motor Voltage |

24VDC |

Applicable Wire Reel |

Φ300×Φ50×103 |

Wire Feeding Speed Range |

1.5–15 m/min |

Wire Reel Capacity |

20kg |

Applicable Wire Diameter |

1.6mm |

Rated Traction Force |

15kg |

Volume |

9kg |

Overall Dimensions (L×W×H) |

460×200×280 mm |

Electroslag Welding Torch Lengths

Model |

Electroslag Welding Torch Length |

Applicable Weld Seam Length |

ZHS (L) |

1000mm |

720mm |

ZSN-10 |

1200mm |

920mm |

ZSN-12 |

1400mm |

1120mm |

ZSN-16 |

1600mm |

1320mm |

ZSN-18 |

1800mm |

1520mm |

ZSN-20 |

2000mm |

1720mm |

Competitive Advantage:

ZH7 inverter slag welding machine is a high efficient and energy-saving DC power supply with IGBT inverter technology, which can weld carbon structural steel, low alloy structural steel, heat-resistant steel and its composite steel.

1、Small volume and light weight.

2、Wide range of current adjustment.

3、The use of IGBT inverter technology to ensure that the welding specifications in the grid voltage and load changes in a highly stable.

4、With protection function, when over temperature or grid voltage is too low to protect, at the same time the protection indicator light. With rectifier output abnormal alarm function.

5、Automatically stop the output if the arc is not established within 1min of starting.

6、High efficiency and power factor, thus it has significant power saving effect and high grid utilisation.